The data collection is crucial in oceanography. But the ocean is a demanding, salty environment, with increasing pressure as you go deeper into it, putting the various components of measuring instruments to the test. Furthermore, collecting data becomes interesting if it can be done with high resolution, and over a long period of time. To meet these challenges, electronics companies have been developing and supplying oceanographic instrumentation since the 1970s, enabling scientists to acquire data from all over the blue planet. Today, this market is dominated by a handful of companies, including RBR, Richard Brancker Research, which is celebrating its 50th anniversary this year. To mark the occasion, we spoke to Didier Clec’h, Director of RBR France.

Can you tell us about RBR’s beginnings fifty years ago and what the company looks like today?

Didier Clec’h : In the early days, in 1973, RBR was housed in the basement of Richard Brancker’s house in a residential area of Ottawa. He worked on integrating and developing sensors to measure really anything; oceanography was then just one field among many. The company began to specialize in oceanography in the late 1990s, when Frank Johnson, who had joined RBR in the 1980s, bought the company from Richard Brancker, who wished to retire. In 2012, Frank handed over to his son Greg, who brought significant innovations to the RBR product range. Step by step, as the company grew, it moved into the adjoining mission before relocating to Kanata, Ottawa’s business district, and eventually to several countries, including Halifax and Seattle in the USA, Qingdao in China, Brisbane in Australia, and France. These international offices enable us to develop projects with our various customers, to get closer to the markets and scientific institutes that are our preferred customers, and to meet their needs as effectively as possible. This is what we do here in Quimper.

Richard Brancker, an engineer, founded RBR in 1973 in response to electronics orders from public institutions. He retired in 1999. © RBR archives

What do you produce today?

D.C. : We design and build various sensors, measuring instruments and systems, capable of being deployed from the ocean depths to the poles, including coastal environments. They enable us to acquire the physical water parameters needed for routine ocean studies: temperature, depth, salinity, dissolved gas content, light intensity, chlorophyll… All our instruments are designed by our R&D team of around 25 people and produced inside the company. It takes two to three years to develop a new sensor. This includes mechanical design, electronic and computer architecture and, of course, a calibration procedure to guarantee data accuracy.

RBR instrument deployments at the poles © RBR

Our instruments can be deployed from boats, on bottom stations or mooring lines, over the entire water column, and integrated into CTD (Conductivity, Temperature, Depth) profilers – structures enabling continuous measurements from the boat. We have also recently developed our own data acquisition systems, such as a winch for yo-yo profiling with a CTD on a ship in transit, as well as software for configuring our entire product range and processing the data.

Immersion of the RBR brevio, featuring a compact CTD sensor © RBR

What are the current challenges for oceanographic instrumentation?

D.C. : The important thing is to guarantee the measurement, to offer a robust, high-performance support, and to make the data collected usable, formatted in software. Today, scientists are asking us to acquire data at ever greater depths in the water column, using all types of sensors. The issue here is the resistance of the materials that make up the sensors’ mechanics: for great depths, titanium is the obvious choice. We recently launched an optical chlorophyll and turbidity sensor, capable of being submerged at 6,000 metres.

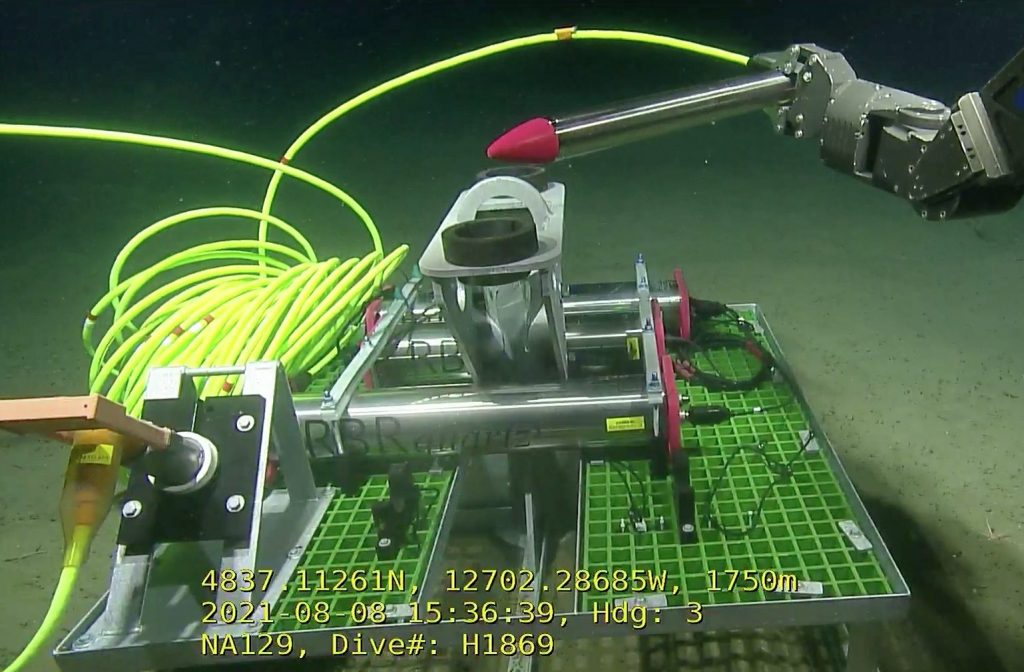

Equipped with a pressure sensor, the RBRquartz instruments, installed on the ocean floor, are designed to observe and measure changes in sea level, tides and tsunamis. Here, they are immersed at a depth of 1750 metres in the North Atlantic.© RBR

The other challenge is to increase deployment time in order to optimise the cost of missions at sea, so we need to offer low-power instruments. We have made technological choices that allow us to use AA batteries (lithium, alkaline, rechargeable), which are now easy to use and relatively inexpensive, while still being easily accessible. Our instruments are deployed just about everywhere in the world, and we need to give the various users the opportunity to be autonomous in terms of instrument maintenance. We have also developed energy management systems for instruments incorporating several sensors to optimise consumption. Finally, we are also working with laboratories at the University of Brest and the FabLab to develop very low-cost, low-power, very compact on-board systems, intended mainly for sailing boats such as the Blue Observer.

RBR has been approved by the Argo programme to use its CTD (Conductivity, Temperature and Depth) sensors on Argo and DeepArgo floats. Some of these have been launched from the Iris, from the Blue Observer company, which offers science under sail solutions. © RBR

The question of duration arises not only in terms of energy consumption, but also in terms of the resistance of materials to the environment, particularly in coastal environments where the impact of bio-fouling is significant, as sensors often become covered in algae, which limits the performance of their measurements. The ideal situation is to be able to take measurements at a fixed point over long periods, without having to take the instrument out for maintenance every month, but without using harmful products either. We have developed a CTD sensor with an active antifouling system that uses UV light to limit the development of biofouling.

As well as developing and producing sensors, is RBR involved in any international programmes?

D.C. : Since 2012, we have been working on the development of a new CTD sensor to meet the needs of the Argo programme (a global programme to collect physical and biogeochemical data by deploying floats). Until now, the programme has essentially relied on a single supplier, obviously a competitor, not least because of concerns about data management and consistency. But scientists have recognised that being dependent on a single manufacturer could be a weakness, so the market has opened up a little. Over the last ten years or so, we have been carrying out tests to obtain validation for the data acquired by our CTD sensors designed for Argo floats up to 2,000 metres and deeper floats (the Deep Argo) which dive to a depth of 6,000 metres. Our sensors have now been validated for this programme. Despite this validation, Argo remains a major project that is constantly evolving.

In 2023, RBR’s instruments and sensors were deployed by various institutes and research centres in different parts of the world to acquire data for the launch and calibration of the SWOT (Surface Water and Ocean Topography) satellite system. It is always interesting to see the international scientific community putting its instruments to work on such a project.

The company works with research institutes such as the CNRS to supply sensors. © RBR

And what are the projects for tomorrow?

D.C. : In addition to what I said about low energy consumption, which is a challenge for today and tomorrow, we are being called upon to increase our observation capacity in deep environments, deep mineral exploration zones, or zones of high geological activity. For example, we have been working with the CNRS in the area of the volcano off Mayotte that erupted in 2018. The challenges include measuring pressure with very high resolution over a long period, but also a wide range of parameters with high resolution and good stability. It is also important to take a close look at what is happening in the coastal environment to provide high-performance measurement solutions to meet the challenges of the future linked to rising temperatures and sea levels.

We are also positioning ourselves in the field of instrumentation for Autonomous Underwater Vehicles (AUVs), developing specific sensors for the various carriers, in particular very low power consumption, simple communications protocols and the shape of the fairing for these autonomous vehicles. Of course, we are always asking questions to anticipate even the needs of scientists, by closely following research. Our teams include oceanographers who work with us on these issues.

About Didier Clec’h

Didier Clec’h is Director of RBR France, a subsidiary based in Quimper.

Didier Clec’h has been Director of RBR France since 2019. Didier Clec’h holds a master’s degree in sensor physics and oceanography, and has been working in the scientific field since 1997. He worked for seventeen years at Ifremer in Brest, starting with five years in the test basin as a test engineer, before joining the ship and onboard systems department to integrate and develop measurement instruments on ships in the French oceanographic fleet. He then worked for the Morbihan-based company Neotek for 7 years, where he developed the marine science department. In 2019, he joined RBR to develop the group’s new business in France and Europe. This new career step will enable him to discover a new environment driven by the world of marine science and the blue economy.

Interview by Maud Lénée-Corrèze